Mercedes Benz Arocs 4151 8×6 – UniCrane Fassi F710RA

Introducing the UniCrane upgrade (flatbed without pillars and tarpaulin, with aluminum three-part sides) with a crane from the Italian manufacturer Fassi, located behind the vehicle’s cabin. This Fassi crane model F710RA, combined with such a powerful Arocs 8×6 truck, represents a reliable partner for efficient cargo handling in all conditions.

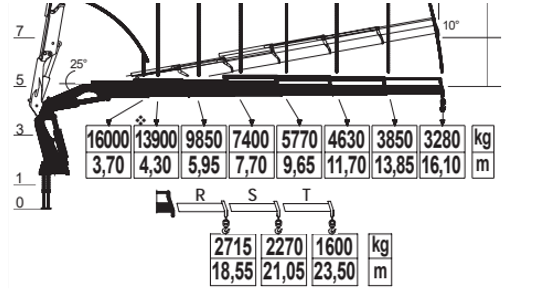

The mentioned crane model Fassi F710RA belongs to the range of heavy-duty cranes. If features 7 hydraulic extensions, 8 functions, and a radio remote control. Thanks to its exceptional load capacity and maximum lifting moment of 68.50tm / 672kNm, it can lift loads up to 30.54m with a jib. The maximum load tis crane can lift is 3280kg at 16.1m or 1600kg at a distance of 23m with additional equipment. Its sturdy construction and resistance to wear ensure durability and reliability in demanding environments.

On the next picture, you can see a load diagram- kg/m.

The truck has eight wheels, six of which are drive wheels, providing exceptional traction and stability on demanding terrains. The drive system can easily overcome mud, snow, sand, and other challenges in off-road driving.

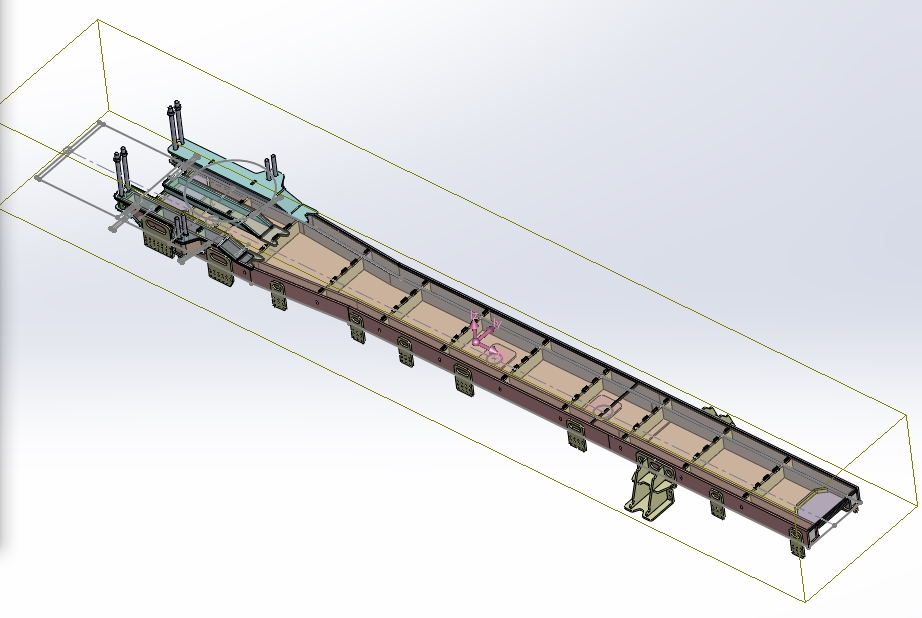

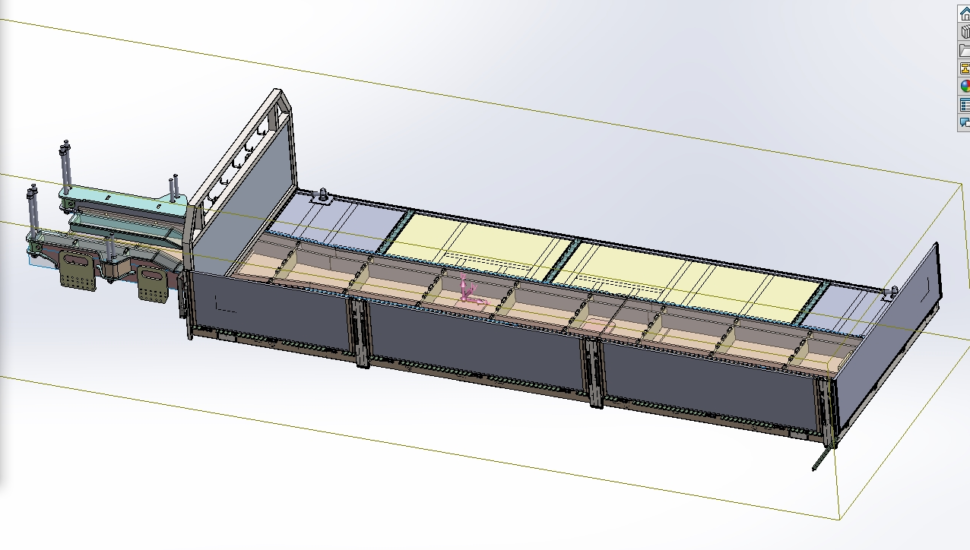

The torsionally “absolutely rigid auxiliary chassis of our own production represents the essence of the vehicle’s quality and enables both the vehicle and the crane to demonstrate their maximum capabilities thanks to it. It is physically separated by 10mm from the main truck chassis, proving that it independently fulfills all the tasks set by the crane, while the truck, with its high maneuverability, can handle all this, and if someone deciedes one day, even set up an electrical grid in the Himalayas.

Of course, a vehicle with such a flatbed without stakes and tarp, external length of 6500mm, width of 2550mm with side panels height of 600mm, and such a bulky crane behind the vehicle’s cabin, ensures maximum safety with hydraulic extendable, swiveling (rotating) stabilizers. These hydraulic stabilizers control the vehicle’s stability and prevent tilting or swaying of the vehicle during crane operation.

The stabilizers extend up to a maximum of 8,290mm, while the rear beam extends up to 4,984mm.

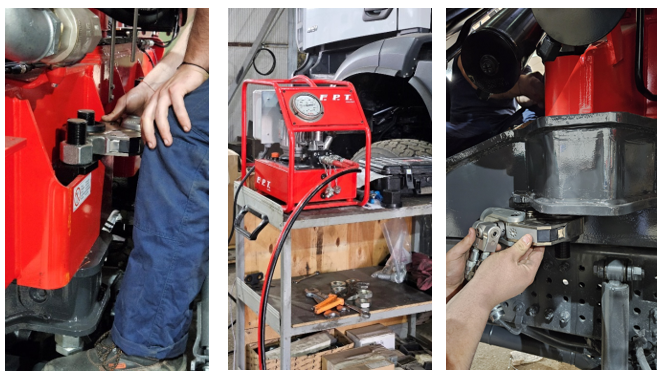

Only a small number of companies engage in installing such large cranes on vehicle chassis. Everything must be meticulously calculated to the fraction of a milimeter, and the installation itself is only possible thanks to special tools, which Uniplast Serbia possesses.

During the installation of this Fassi crane, due to its size and high load capacity, we utilized our bolt tightening machines. Using a hydraulic torque wrench, we tighten the bolts with the prescribed force, following the crane manufacturer’s instructions and parameters. Our system for tightening large screws on bigger cranes includes electric and pneumatic pumps for tool control, along with double high-pressure hoses. By employing our top-notch equipment, crane safety during operation is elevated to a high, or perhaps modesty aside, we could say the highest level of safety, which is crucial for such large cranes. Watch the video for screws tightening during crane installation using a hydraulic torque wrench https://www.instagram.com/p/C5sbyDvCID3/?hl=en

The front side of the flatbed is made from a single piece of profiled steel sheet, measuring 1200mm in height, to protect the crane from the transported load without interfering with the crane’s operational work.

As for the optimal distribution of weight relative to the vehicle dimensions, a spare wheel is located at the rear right side of the vehicle, while the free space on the left side is utilized for installing a stainless steel toolbox for tools, wrenches, and other work equipment.

This Mercedes Arocs 4151 8×6 with a flatbed and Fassi F710 crane embodies a blend of exceptional strength, reliability, and functionality, making it a top-tier combination that delivers the necessary efficiency and perfomance in the construction and transportation industries, as well as in energy installation. There for, it is a fitting and excellent choice for the customer “Kodar Energomontaža,” a leading regional EPC company.