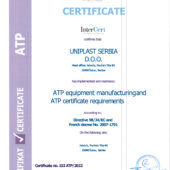

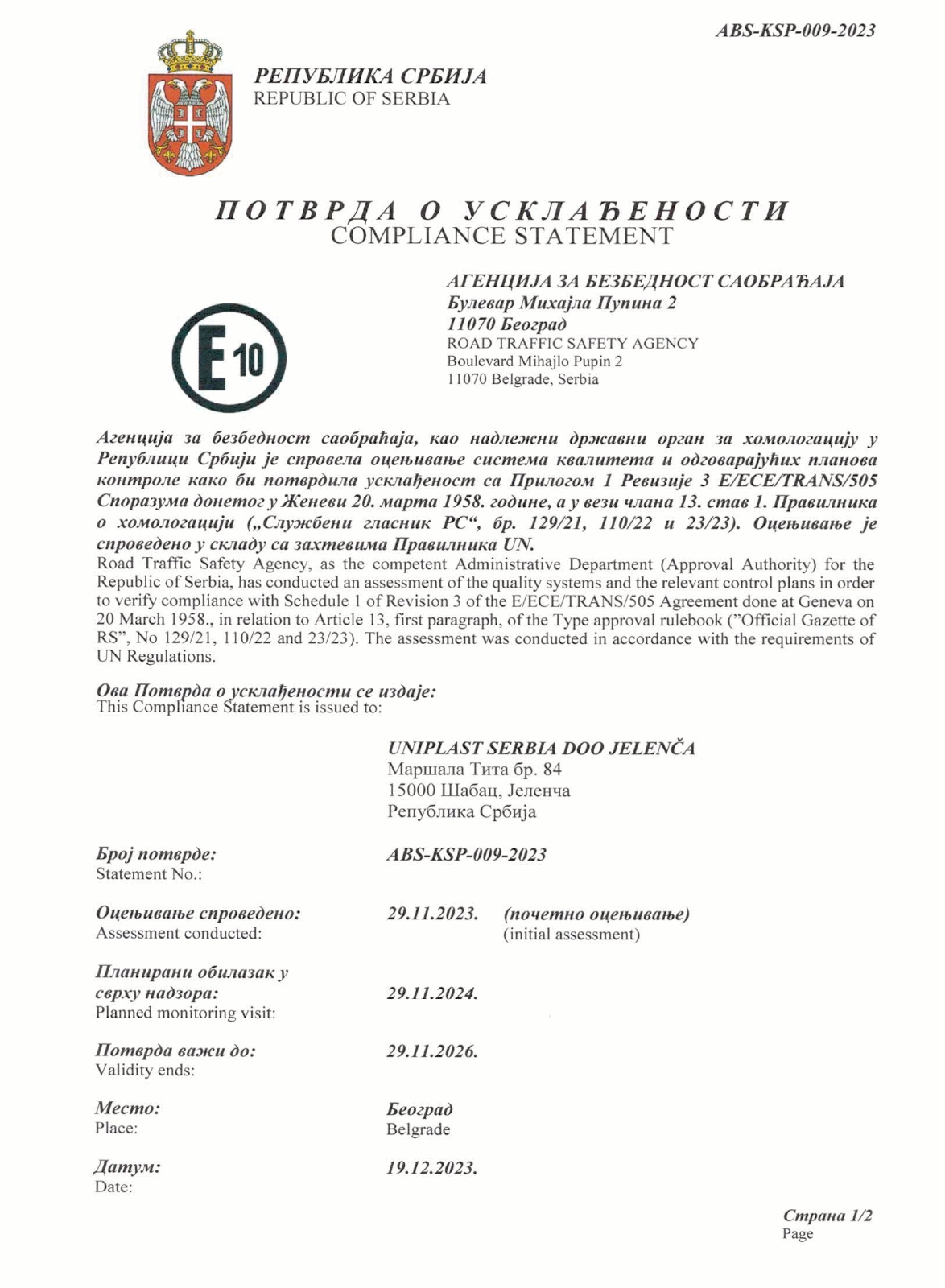

ABOUT US / CONTACTS

We are passionate in our work.

Uniplast Serbia is offering solutions, while taking customer

needs into consideration, and delivering products of such quality that the

whole existence of the company is based on it – on domestic as well as on

international markets – using technology and materials which are considered to

be standard in production of this type of products and also, materials which do

not endanger the environment. Every problem is considered to be reclamation,

and everyone is in the company is expected to work on it’s removal, for which

we have developed and systematical approach.

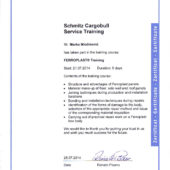

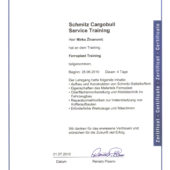

Our motto „Reinforced with experience“ expresses our

aspiration to expand the company by making our cadre and brands strongers, and

to make our product permanent value which can be exploited without regular

servicing. For our buyers this means, quick return of the investment and

expanded inter-service period. Only the above mentioned system can enable

repeatability and traceability, quarrantee stated requirements, and for is in

ensures the stability of workplaces.

With our activities „Uniplast Serbia“ not only

satisfies customer needs, but also

ensures a good living standard for our employees.

The most important is realize and systematically fulfill all

promises and obligations, and experiences gained are archieved as permanent value.

Šabac, 25. 11. 2007.

Miroslav Živanović