Instalation of additional air capacity on tractor

FOR SAFE BRAKING OF HIGH TRANSPORT VEHICLES (GCW 225 t)

SECONDARY OPTION: FINISHING HYDRAULICS, MAKING DRAWERS, SPOILERS BEHIND THE CABIN, LED LIGHTS …

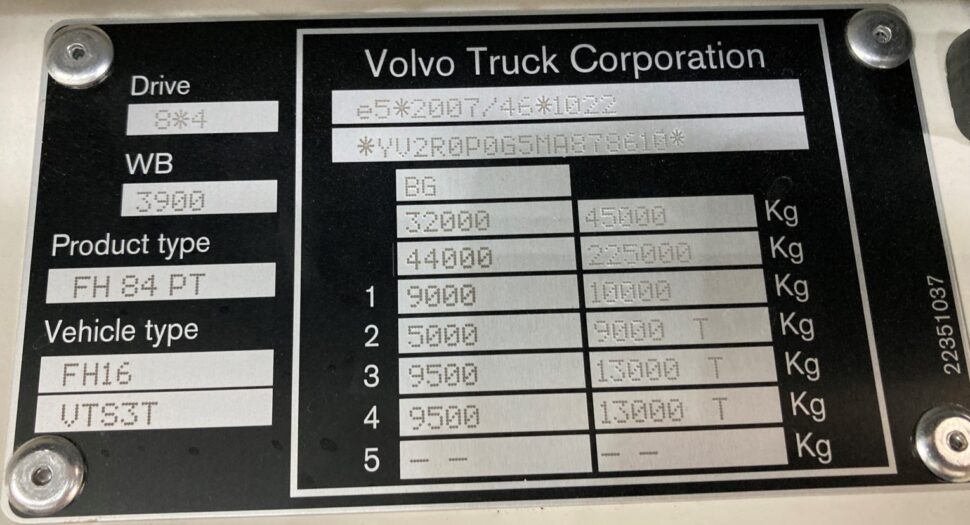

We joke a little, but as in every joke, there is truth here, and that is that even such a powerful Volvo cannot do without us. We also have a solution for those clients who buy a powerful and demanding high-capacity semi-trailer for oversized transport from us, and at the same time order an adequate tractor that has a standard prepared vehicle, so that they can attach it to a suitable tractor. This is where we perform and in a shortened procedure “fatten” the ability of that tug to the required “strength and weight”.

In the next photo you can see what this beautiful 8×4 looked like when it arrived in the circle of our company, ie before our finishing, although with the tile from the photo above this text already saved.

In order to be able to tow oversized semi-trailers in the next jobs and show all its strength and functionality, it was necessary to refine this chassis and make it more universal, as well as capable of justifying these 225,000 kg of gross combined weight.

The first and most important thing was to make the possibility of safe braking of the tractor brake system in combination with a multi-axle low-loader semi-trailer, which we did by adding a “row” of 6 air tanks (a total of another 150 liters), behind the cab, hidden in the newly formed contractions, placed at the very top.

Of course, in addition to solving the brake installation, we also dealt with hydraulics, where we finished the hydraulic set, whose set contains:

• oil tank in the rear cabin, AL material, capacity 160L

• oil return filter mounted on the tank, 175 l / min, 25 min

• valves and latch for the tank valve

• maximum safety valve 1 ”

• quick couplings, for thread type, sa “with taps, 2 sets

• quick-connect bracket

Of course, in addition to increasing the air capacity required for safe braking of the combined vehicle, as well as the mentioned hydraulics, other improvements were made, more visible to the naked eye in the photos that follow.

These refinements, ie improvements, went in several directions, but we covered everything with made and installed side spoilers, which beautified the cabin, but also brought aerodynamic improvements that reduce fuel consumption costs, because the air resistance is lower.

Behind the cabin we made 3 cabinets with compartments and efficient roll-up doors, for tools and equipment, and on top of the body we installed additional working and signal LED lights, as well as an LED reflector on the roof of the cabin.

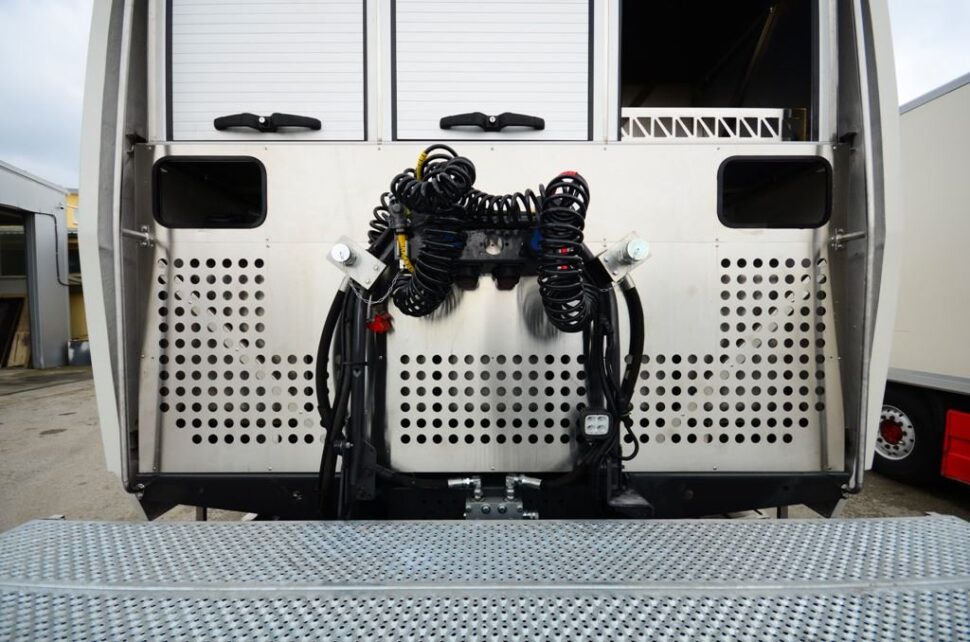

In addition to the already factory-installed pneumatic connection for the semi-trailer – DUOMATIC system, we also installed standard EC couplings in parallel, and a NATO connector on the cabin itself (hidden in the body, above the cabinet).

Under the cupboard, we placed a stainless steel sheet that covered the oil tank and other equipment, included in the complete hydraulic set for the tractor.

We also made and added a platform with a perforated Al-insert in front of the fuel tank, wear-resistant, with a carrying capacity of two people. Of course, steps and a handrail for climbing on all those platforms were also made.

On the back of the chassis, we produced and installed a portable panel, ie. a support plate, which is necessary as a support for the support neck (in the King Pin zone) of the semi-trailer.

After the work described above, this tractor leaves us completely “tuned” and ready for new challenges. The 225 t can now be safely towed!