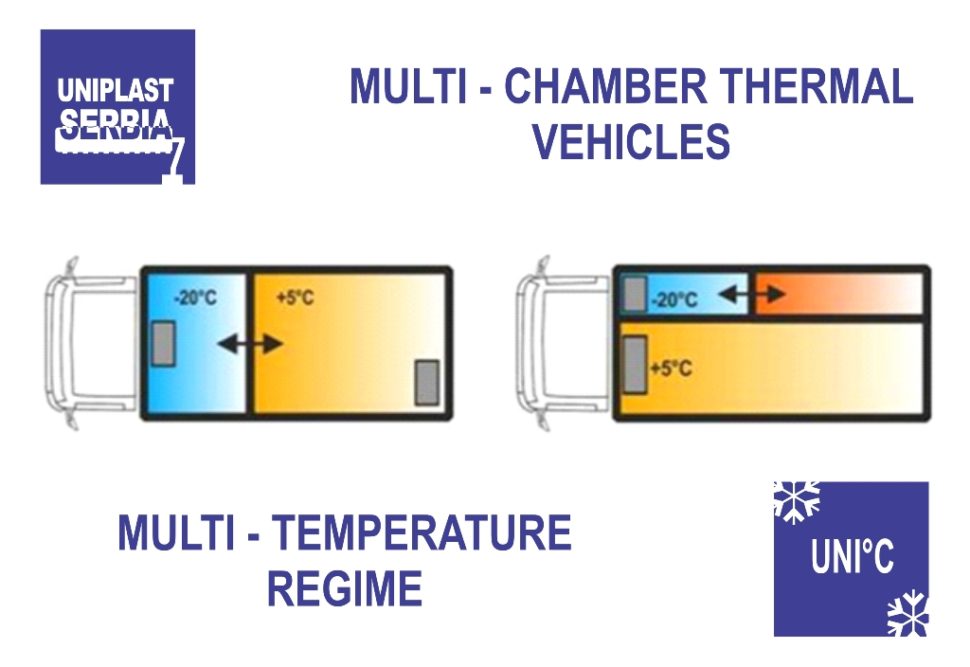

Logistics with efficient (multi-chamber) termal vehicles (multi-temperature regime)

In order to supply large commodity chains to different types of products, these vehicles are a hit, as the trend towards linking products is increasing, and the supply and logistics of large customers in the food sector can be done easier and faster with the right delivery vehicles, vehicles that have a prefabricated factory space. Multi-temperature refrigerated vehicles are the economically viable solution for such a way of logistics.

The unique offer of large food buyers – gastronomy, canteens, food sellers, gas stations, bakers – with a range of products in different temperature ranges can save many kilometers of transportation and thus costs. Of course, refrigerated vehicles must be equipped accordingly.

What excellent refrigerated truck (refrigerated thermo box) need for an efficient temperature controlled delivery of food? First of all, it is important that the ordered goods arrive in perfect condition, hygienic and on time. An efficient refrigerated vehicle is therefore very integrated into logistics processes.

This is especially true if the principle of economic logistics is “one order, one delivery, one invoice”, as a rounded process. In this way an efficient thermal or cooling vehicle is also included in logistics IT systems. One of the key words is security, and Uniplast Serbia Chamber, better known under the brand name UNI°C, can withstand almost all options.

Usually, there are five different temperature ranges in food logistics:

- Frozen area: -18°C and colder when transporting frozen goods such as ice cream, frozen ready-made dishes, frozen vegetables, frozen fish, meat and bakery products;

- Ultra-fresh range: 0°C do +4°C, fresh milk, soft cheese and sausage products, salads, also prepared salads, poultry, raw pasta products, convenience products depending on the manufacturing stage;

- Freshness range: +4°C do +7°C for products such as cheese, smoked products, ham, some fruits and vegetables;

- Ambient range: +14°C do 21°C for products such as chocolate, sweets, coffee, red and white wines, drinks in general;

- Dry cargo range: above 0°C for products such as preserves, pasta, nuts, flour, sugar, legumes, rice and non-food products.

As a rule, refrigerated vehicles with two or three temperature ranges (3-chamber solution) are used. Temperature ranges are adjusted to the current load range, which naturally depends on the size of the loading area.

Multi-temperature cooling chamber with longitudinal partition panel

Multi-temperature cooling chamber with longitudinal and transverse panel

Multi-temperature cooling chamber with ergonomically optimized cross sectional panel

UNI°C partition panel Uniplast Serbia

Cross partition panel Uniplast Serbia

Uniplast Serbia offers several built-in systems for multi-chamber solutions. We offer built-in systems that allow a fixed or flexible longitudinal or transverse distribution of the cooling chamber. Since we are completely oriented to the wishes and needs of our customers, as well as completely individual solutions adapted to the specific application of the cooling vehicle can be feasible. Division of load compartment longitudinally and transversely (partition panels), adjustable and foldable. The split is sometimes done on used chambers, in order to subsequently increase safety and efficiency in transport.

This investment related to refrigerated boxes (cooling chambers) or in transport in general is always worth the money.